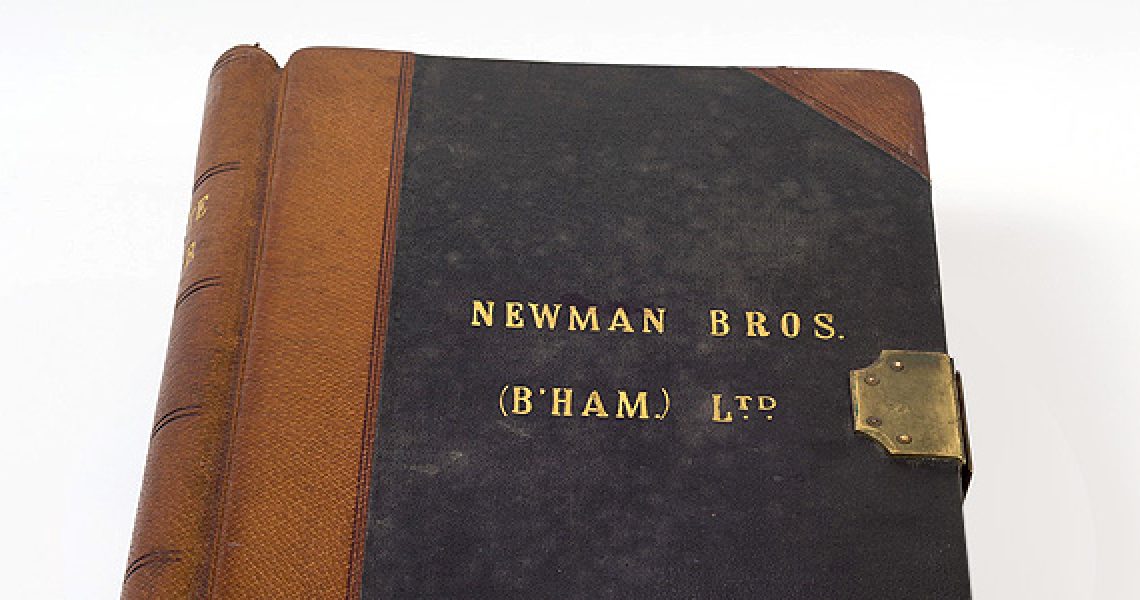

Over the past couple weeks, one of our volunteers, Lindsay, has been looking into the accounting ledgers of the Newman Brothers’ business. She has written her findings for our visitors to get a sneak peek into parts of the business that have previously not been available to the public. We hope you enjoy!

Costs are expressed in pounds, shillings and pence (£sd).

PLANT AND MACHINERY:

Plant and Machinery is an interesting account to look at as it shows, in detail, all the sales and purchases of machines and other equipment. This in turn gives an indication of when production methods may have changed.

Here is a timeline with the major changes in the plant and machinery accounts from 1916 to 1959 which is as far as we have found, so far, in the records:

1916 – The earliest year for which we have a Plant and Machinery account, and this shows that Newman Brothers owned plant and equipment that had originally cost £787 12s 8d. There are no further large movements in the Plant and Machinery accounts until 1938.

1938 – A gas engine was sold at a loss of £214 8s 8d.

1945 – Purchased a motorised pillar drilling machine and three lathes for £157 2s 9d.

1949 – Purchases included the following:

| £ | s | d | |

| Equipment for nickel tank | 342 | 13 | 6 |

| Degreasing plant | 55 | 6 | 5 |

| Dust extracting plant | 96 | – | – |

| Polishing spindle motor | 48 | 12 | – |

| Fixing rectifier and air pump | 45 | – | – |

Also, various worktables, hoods, pipes, lathes, nickel anodes, weights and a standard press.

1950 – Purchases included:

| £ | s | d | |

| Rhodes motorised power press | 150 | – | – |

| Three immersion heaters re nickel vat | 73 | 14 | 9 |

| Steel shaking barrels with pulleys | 86 | 15 | – |

Also, electrical equipment, motors and tanks.

1952 – There continued to be investment in production machinery and equipment despite a large net loss in the accounts for 1952. However, after this year the profitability of the business seemed to increase.

Purchases included:

| £ | s | d | |

| Supplying plant and installing for Copper and Silver

Oxidising Plating press. |

829 | 15 | 9 |

| Plating barrel | 75 | – | – |

Other purchases included various tanks, ducts and Bench Type Counting machine.

1954 – Purchases now included some office equipment:

| £ | s | d | |

| Gear unit with electric motor | 40 | 19 | – |

| Rebuilt typewriter | 39 | – | – |

Also, an engraving machine, dynamo, motor and guillotine.

1956 – A significant investment in the shroud room including:

| £ | s | d | |

| 11 sewing machines (8 no. 24, 2 no. 95, 1 4-needle and 1 6- needle) | 300 | – | – |

| Cutting out press | 310 | – | – |

1958 – A large investment in Plant and Machinery across the board which possibly paved the way for the increased profits in the 1960s. Major purchases were as follows:

| £ | s | d | |

| Typewriter | 59 | – | – |

| Gestetner duplicating machine | 40 | – | – |

| RK cutter | 100 | 19 | – |

| Pfaff sewing machine | 66 | 8 | 7 |

| Lockstitch sewing machine | 56 | – | – |

| EH24 Mark III High Vacuum Coating unit SN 4019 | 1,775 | 18 | 11 |

| Electronic control unit | 444 | 1 | 1 |

| Curing gas heated oven | 176 | 13 | 6 |

| Rotating spindle jigs | 258 | – | – |

| Installation of water supplies and waste to Vacuum machine workshop | 78 | – | – |

1959 – Another year of investing in plant and machinery

| £ | s | d | |

| Six more Pfaff sewing machines | 372 | 17 | 9 |

| Addwell electronic adding machine | 55 | – | – |

| Installation and rearrangement of gear in the plating shop | 50 | – | – |

| New Bright Nickel-plating plant | 85 | – | – |

| Fitting compressor | 55 | 9 | 3 |

| Second hand spray booth | 86 | 5 | – |

| Second hand rectifier | 200 | – | – |

| Electric Dome filter | 85 | – | – |

And this is where we are for now, but I am sure that some of you will understand what these machines were used for and what it means in terms of changing production. As we find more, we will keep you updated.

If you have any thoughts, ideas, or questions you would like to ask please drop us a line via email on newmanbrothers@coffinworks.org .

If you missed out on the first two instalments in our “Tales from the ledgers” series, please click the link below to look into the net profit of the business. Do keep an eye out for later instalments in the following weeks.

https://www.coffinworks.org/tales-from-the-ledgers-profit/

By Lindsay Whitlow, Volunteer